Industrial warehouses

Storage of high-added-value products, creation of production workshops, testing of new equipment and/or processes...

Large spans, high heights for maximum volume and a controlled budget

The robustness of a traditional building combined with the flexibility of a modular structure

Built to measure for a temporary or permanent installation evolving with your needs

Your turnkey building in less than 6 months.

Excellent cost/m3 ratio

The construction uses the minimum amount of material.

It adapts to changing needs.

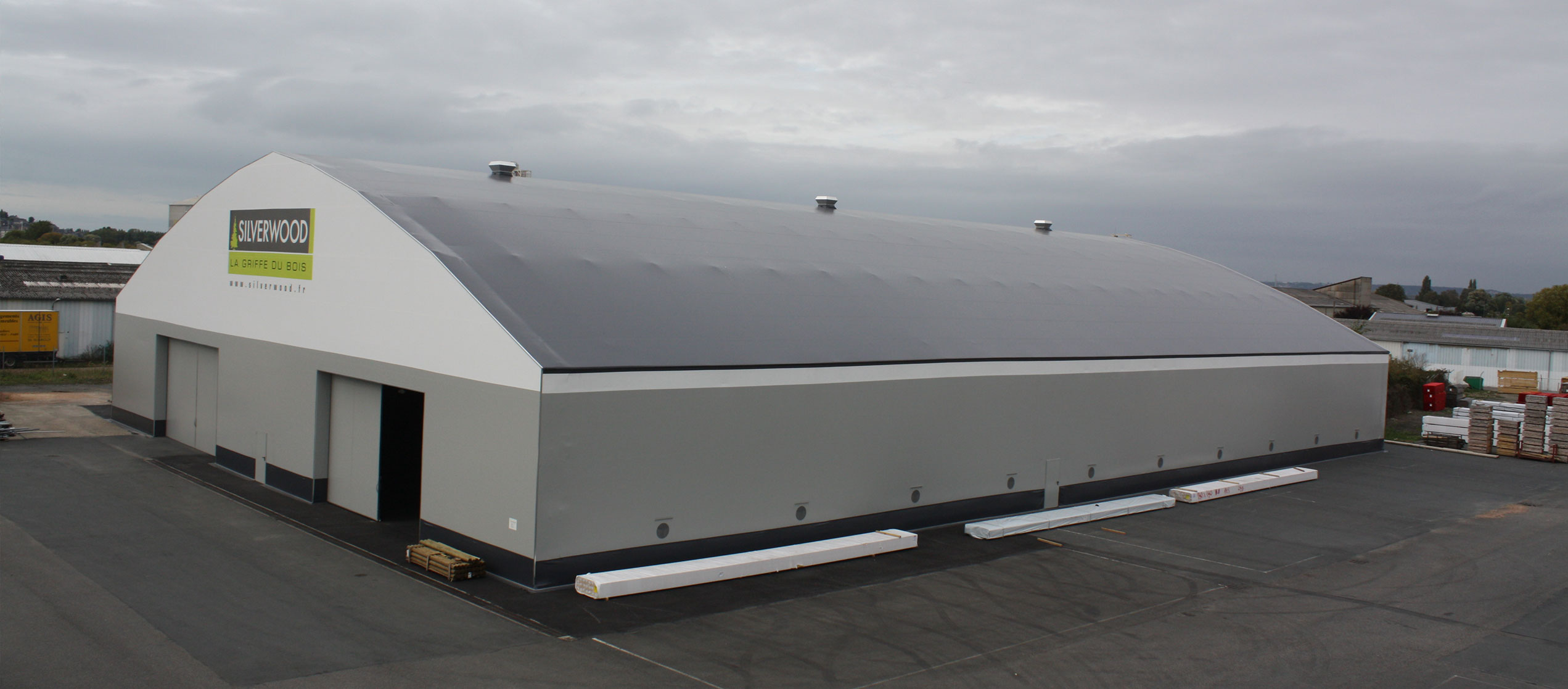

Metal Textile Building XXL

The XXL metal-textile building is a suitable solution for all storage needs at rack height and with a wide span and/or that environmental conditions require the installation of an extra resistant structure.

Storage of high-added-value products, creation of production workshops, testing of new equipment and/or processes...

Lhe proposed large heights and spans facilitate exploitation and optimise the surface area on the ground.

Large-size buildings

Tensioned membranes are able to withstand the pressures of wind and snow.

Doors and gates

Non-standard dimensions

With its extraordinary volume and geometry, the Schwarzmann range of buildings is perfectly suited to the requirements of logisticians and industrialists looking for high-performance storage solutions.

Designed for extreme conditions

Based in Austria and Slovenia, Schwarzmann has been designing, manufacturing and installing large-format metal-textile buildings throughout Europe for over 30 years.

Its geographical location and its very strong penetration of the Swiss and Austrian markets have forced it to push the limits of the constraints that the structure can withstand, linked to alpine snow loads, while guaranteeing impeccable quality adapted to the standards of its main customers.

Perfect finishes

Schwarzmann buildings are made using a galvanised steel lattice frame covered with a pre-stressed flexible Serge Ferrari composite membrane (leading French manufacturer of composite fabrics known for its stadium covers in particular) fully welded and bonded to the structure to form a one-piece roof.

Locabri's teams will support you in setting up your hangar

The implementation is controlled by Locabri, guaranteeing quality site monitoring and the ability to organise the supply of all the equipment necessary for proper operation: openers in all motorised and non-motorised formats, lighting, HVAC, etc.